Paper production is one of the industrial activities regarded as a pointer to a nation’s level of industrialisation and educational development, and this sector should be maximised using local resources.

That is the submission of the Director-General, Raw Material Research and Development Council (RMRDC), Prof. Hussaini Doko Ibrahim, in a statement made available to The Guardian.

While the use of computers and other forms of technology for data storage and retrieval is on the increase worldwide, the demand for paper has also continued to rise.

Over 300 million tonnes of paper are used globally in a year and the Food and Agricultural Organization has predicted that demand for paper products will increase globally by 50 per cent in 2050.

In Nigeria, in the early 1960s, three integrated pulp and paper mills were established to produce a paper of different types for the local and export markets. The paper mills are the Nigeria Paper Mill (NPM) in Jebba; Nigeria Newsprint Manufacturing Company (NNMC), Oku Iboku and the Iwopin Pulp and Paper Company (IPCC), Iwopin.

According to the 1994 annual report of the CBN, the import of newsprint reduced drastically to 17.5 per cent in 1986 and 12.5 per cent in 1987 and faded out in 1988. NNMC was the only newsprint manufacturing company in West and Central Africa.

Since 1996 till date, the country has depended mostly on the importation of different types of paper products, except packaging materials, some of which are being produced by NPM and four other paper mills that are producing kraft papers from recycled waste paper.

According to COMTRADE 2022 database on international trade, Nigeria imported paper products amounting to $696 million in 2020 alone. Some of the countries some of the products were imported from included China with a share of 24 per cent of total imports in 2020, Indonesia, 11 per cent; India, 11.9 per cent and Egypt, 2.11 per cent. Ironically, some of these countries use non-wood fibrous resources in their raw materials resources mix. Apart from the expenditure of scarce foreign exchange, over 300,000 jobs are lost due to paper importation.

In Nigeria, various studies have indicated massive availability of different fibre resources, including recycled fibres, that may help in transforming the paper industry landscape if adequate investments can be made in utilising them for paper production.

Since its commences operation in the 1960s, NPM had used waste paper as one of its major raw materials. The company is still recycling waste paper.

It is however interesting to note that the availability of waste paper has reduced very considerably as about three or four other companies have come on board to produce packaging materials from recycled fibres in Nigeria.

The RMRDC boss also disclosed that research and development had led to the discovery of Sterculia setigera and Steculia oblonga with fibre lengths higher than 2mm.

“Apart from this, Nigeria has a number of non-wood raw materials. These are speciality non-woods or softwood replacements such as cotton linters, kenaf and bamboo, among others, and common non-wood or hardwood alternatives such as straws, bagasse, corn stalks and sorghum stalks,” he said.

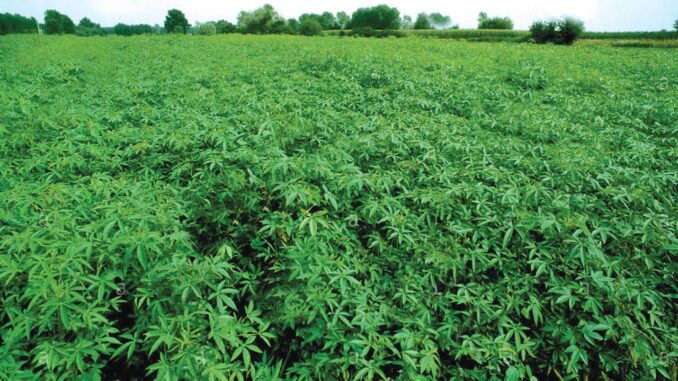

“Kenaf has been used as a substitute for wood pulp and paper production in Thailand and China, Prof. Ibrahim explained, and studies carried out in Nigeria shows the fibre length of kenaf bast to be 2.90mm, while the fibre diameter is 28.16 um, lumen width of 6.08 um and cell wall thickens was 11.04 um respectively,” he added.

In the recent past, RMRDC collaborated with the Institute of Agricultural Research and Training (IAR&T), Ibadan to produce foundation seeds of kenaf, which were multiplied by the Kenaf Association of Nigeria (KEAN) in Kwara State.

This collaboration with IAR&T, later led to the production of four varieties of kenaf breeder seeds for further multiplication by the association. RMRDC has also carried out a technical study on commercial-scale pulping of bast kenaf fibres for long fibre pulp production. The report is available for use, study or consultations by investors.

In addition, five species of bamboo are indigenous to Nigeria. The most prominent one of these is Bambusa vulgaris. The pulping properties of the species have been studied, the council said.

The fibre length varies from 2.37-2.92mm, showing that strong paper with good tearing resistance could be obtained from the plant. It is one of the fastest-growing plants in the world. It was commercially used for kraft paper production by the NPM before its closure in 1996. Bamboo is also popular as raw material for pulp and paper making in China, India and Malaysia.

RMRDC constituted a team made up of experts from UI, FUTA and RMRDC to carry out a nationwide survey of bamboo availability and utilization in Nigeria. The study indicated that bamboo is widely distributed especially in the south and middle belt regions. RMRDC is presently collaborating with a number of investors, most especially, Gamla Nigeria Limited, to establish a bamboo plantation in Delta State.

“To optimise pulp and capacities, a mix of big, medium and small-scale paper-producing mills will have to be encouraged. Small scale paper production has the potential of low initial capital.

“This makes it easy for prospective investors. There is a need to support this initiative through policy measures such as tax cuts, increase tariffs on paper and paper products produced by the mills and mandatory usage of locally produced paper in industries, schools and government offices. This was the approach adopted by India in the 1970s,” Prof. Ibrahim explained.

He advised that to encourage development of non-wood small-scale pulp and paper-making industries in Nigeria, there is a need to earmark certain products exclusively in the domain of the small-scale paper industries to protect them from competition from the large-scale mills that have been privatised.

“Also imperative is the improvement of access to credit, technology, skill and market information. Establishment of mills that will pulp the fibrous raw materials that are locally available will save Nigeria more than N500 billion yearly in foreign exchange equivalents,” Ibrahim said.

END

Be the first to comment