Maximizing import substitution strategy using local contents, jute bags, which cost the country about N2.75 billion yearly to import, and other environment-friendly products such as vehicle parts can be developed from kenaf and save the country from economic crises. Jute bags are used in packaging and post-harvest storage of dried cocoa beans, cashew nuts, coffee and other farm produce.

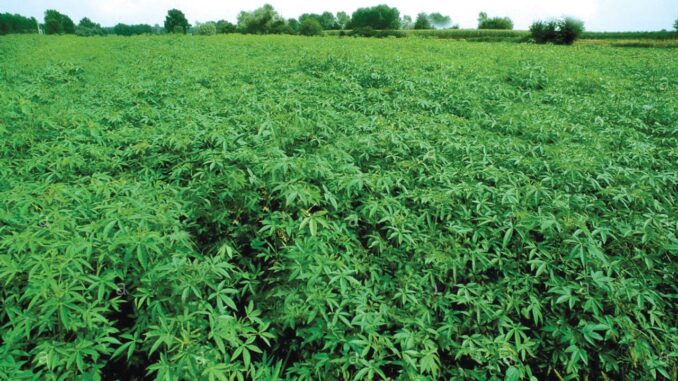

Kenaf (Hibiscus cannabinus L.) is a multi-purpose bio-economic crop. It is a fast-growing, annual crop that belongs to the Malvaceae family. It belongs to the genus Hibiscus that comprises about 400 annual and perennial species. Kenaf has been associated with over 120 common names, such as mesta, treal, roselle, ambary hemp, and rama, indicating how widespread and diverse the species is.

It has been hailed as a multifunctional crop that has the potential of replacing crude oil in several applications.

Considering the current global environmental challenges, the need to return green or bio-economy has become imperative. There are four major motivations behind this. Bio-economy will lead to improvement in the quality of the environment; improve agricultural production and productivity, national food and social security and a stronger and sustainable economy.

Kenaf, as a renewable commodity, presents an unlimited opportunity as a promising source of energy, food and industrial raw materials. Kenaf bio-economy represents one of the most promising ways to secure sustainable economic growth and industrial development and environmental amelioration resulting from population growth and over dependence on petroleum resources. Therefore, development of kenaf bio-economy in relevant nations like Nigeria will lead to green growth of economies.

Director-General, Raw Material Research Development Council (RMRDC), Prof. H.D. Ibrahim, said: “The industrial attractiveness of kenaf lies in its stem, whose diameter varies from 25-50mm. The kenaf stem is composed of an inner porous and woody core which consists of about 60-65% of the stem.

“The core contains short fibers of an average length of between 0.6 mm-length, and 33 μm-width. The outer fibrous bast consists of about 35 – 45% of the stem and contains long, strong, and valuable fibers for industry. The average fibre length of the fibrous bast is about 2.5 mm-length and 17 μm-width. Due to the differences in fibre anatomy and properties, the bast and core have different industrial applications.’’

He explained that they, however, have to be separated through retting, ribboning and decortication. The traditional retting method occurs in the field, where the stems are harvested and left in the field for several days, allowing them to rot naturally by air, dew, and common bacteria.

“Often, the stems are submerged in water ponds, canals, or tanks to accelerate the process. On industrial scale, this is done by either enzymatic, chemical/ mechanical, chemical/enzymatic or steam explosion methods.

“On the basis of industrial application, kenaf is used for cordage, woven and non-woven textile products. Kenaf bast and core fibers are used as reinforcing fiber in bio-composites. It is also used in particle, hard, and insulation boards, compression-molded products, laminates production, etc. A blend of 40% kenaf fibers could be substituted to wood flour fillers and combined with virgin plastics such as polypropylene or recycled low density polyethylene,” he added.

Analysis of kenaf indicates its core panels usually present much lower densities (218kg m-3), thermal conductivity, and higher acoustical properties than traditional wood panels, which makes them ideal for ceiling tiles, doors, or walls and furniture. Medium density fiberboard panels made out of kenaf bast can be, therefore, used for laminated floors and cabinet doors, among others.

“The Toyota Motor Corporation in Japan uses kenaf bioplastic interior components for its Toyota Lexus GS. It reduced the weight of the vehicle, and consequently, fuel consumption and CO2 emissions. Also, Panasonic Electric Works makes structural wall board with kenaf to replace plywood. Likewise, kenaf could be converted into heat, bio-power, bio-fuel and chemicals.

“The kenaf core is very porous and is attractive for absorbent applications such as wipes, hygienic products, water filtration system, bedding for livestock, poultry or rodents. This is because kenaf acts like a sponge in terms of urine, odors and dust,” Prof. Ibrahim added.

Researchers also said oil spill cleaning is a very important area where application of kenaf could be useful. It was used as one of the oil absorbents during the BP oil spill in the Gulf of Mexico in 2010. As a natural filter, kenaf is used to improve soil and water quality. Along with papyrus and sorghum, kenaf has been shown to present the highest nitrogen and phosphorus removal rates, especially during the summer and fall. Nutritionally, Kenaf leaves are rich in crude protein. The leaves contain 14 – 34% protein, while the stalk contains about 2 – 12%. The leaves are used as human food, similar to spinach, in India, Haiti and in some areas of Africa.

In produce packaging and post-harvest handling, jute sacks are old traditional sacks made from jute and kenaf fibres. They are extensively used for packaging materials in the Middle East, Africa, Asia and many less developed countries. They are strong and coarse bags, normally used for carrying heavy produce with adequate ventilation.

Bangladesh is the leading exporter of jute and kenaf bags, followed by India and China. The three countries account for over 90% of the world export. The principal importers of kenaf products, especially sacks, are the countries producing large volumes of agricultural commodities like USA, United Kingdom, Japan, Germany, Netherlands, some African countries, etc.

Nigeria can play a significant role in the production of jute bags, which are bio-degradable, environment-friendly and cost-effective. This can increase the gross domestic product (GDP) significantly through export and home use.

Development of kenaf bio-economy in Nigeria is plausible and very attractive, as Nigeria has over one million hectares of land suitable for its cultivation in about 18 States of the federation, including Adamawa, Bauchi, Gombe, Taraba, Plateau, Kwara, Kaduna, Benue, Kogi, Niger, Nasarawa, Lagos, Ogun, Osun, Oyo, Ekiti and the FCT.

Experts have said due to the collapse of the first national initiative on jute sacks production in Jos and Badagry by Nigeria Fibre Company (NIFINCO) and Nigeria Fibre Production Limited (NNFPL) around 1971 and the increase in jute sacks requirement from 2 million pieces to 5 million pieces, it is imperative that efforts be made to revisit the production of jute sacks in Nigeria.

This is more important as the cost of jute sack importation is about N2.75 billion in foreign exchange equivalent yearly. The situation is becoming very pathetic as a number of commodity exporters have resorted to importing second-hand jute sacks from Ghana. This has contributed to further rejection of many agricultural produce being exported from Nigeria.

To promote kenaf bio-economy in Nigeria, the Institute of Agricultural Research and Training, (IAR&T) Ibadan, and RMRDC have promoted kenaf varietal development and domestication of improved varieties of imported Cuba 108, Cuba 2032, Everglades 71, Guatemala 3F.

This was followed by multi-locational-field trials of the imported improved kenaf seeds in the South-West geo-political zone during which only Cuba 108 was found to be most adaptable to the local environment and cultural agronomic practices.

In addition, the technology for the design and fabrication of kenaf decorticating machine is now available locally. With these achievements, the country is ripe for sustainable development of kenaf bio-economy. However, this is only achievable if investors are ready to invest in kenaf processing in Nigeria.

END

Be the first to comment