FEMI IBIROGBA writes on the need to promote homegrown technologies towards commercialisation of agriculture and ensuring food security.

Homegrown science and technologies have been described as invaluable resources in the efforts to promote agriculture and its value chain development in Nigeria.

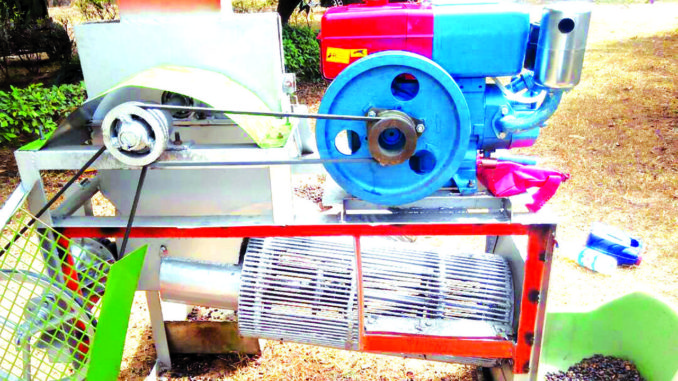

Agricultural technology is scientifically designing and fabricating devices, tools and techniques capable of reducing raw labour, increasing productivity and enhancing efficiency of crop production/protection, harvesting, preservation and processing.

Nigeria is said to spend about $3 billion annually on importation of foreign goods, including agricultural tools.

Local manufacturers, through Dr. Frank Jacobs of the Manufacturers Association of Nigeria (MAN) and the Agricultural Machinery Equipment Fabrication Association of Nigeria (AMEFAN) say they lose this sum to competition due to preference of Nigerian government and consumers for foreign goods.

He said: “Undoubtedly, the government remains the largest single spender in the economy and could drive industrial development and economic growth by increasing its patronage of locally made products.

Government prefers foreign goods and Nigerian manufacturers lose an average of $3bn annually as a result.

“It is an established fact that when we buy foreign goods, we pay the returns to factors used in producing them in the originating countries. That is to say that we pay wages, rent, interest, and profit to foreign countries with our local resources.”

Realising the significance of mechanization through homegrown technologies, the Nigerian Incentive-Based Risk Sharing System for Agricultural Lending (NIRSAL) Plc, the Federal Ministry of Agriculture and Rural Development, the African Development Bank (AfDB), the International Institute for Tropical Agriculture (IITA) and other players in agriculture recently planned a robust investment in technology to boost yields and generate gainful employment for the country.

The AfDB pledged to invest $120 million in local technologies over the next three years to boost productivity and transform nine commodities, including cassava, rice, maize, sorghum/millet, wheat, livestock, aquaculture, high iron beans and orange-fleshed sweet potatoes in Africa.

Similarly, Dr Ayo Oduntan, during a lecture on unlocking Nigeria’s potential in agric for sustainable development in May at the inaugural 2018 public lecture held at the College of Agricultural Science, Olabisi Onabanjo University, mentioned technology and equipment fabrication as a tool to developing the sector.

Mrs Obiajuru Luya, Managing Director of Farmhouse 360 Ventures, producers of processed bitter leaves, in July, also called for establishment of more incubation centres to drive indigenous technologies in agriculture.

“The facilities in each centre must be relevant to value chains that are predominantly in each location,” she said, urging that the government should implement policies to promote food sustainability and economic growth.

As in other sectors, Nigeria is import-dependent on agricultural equipment and technologies despite myriads of colleges of agricultural technology, universities and private equipment makers.

The Chinese government has been paying great attention to the ever growing demand for food and rural development and realizes the importance of agricultural modernisation for attaining the same.

To cover the technological gap between the domestically manufactured and imported products, the government is also open to the establishment of joint ventures between Chinese and foreign enterprises. In return, the multinational companies enjoy access to the vast Chinese market.

In that country, favorable government policies have greatly motivated equipment makers to invest in tools production lines.

National Centre for Agricultural Mechanisation’s (NCAM’s) efforts

MR Taye Olaifa, Public Relations Officer (PRO) of the National Centre for Agricultural Mechanisation (NCAM), Ilorin, while explaining the need for locally manufactured agric equipment, said one of the mandates of the centre is to produce simple, local and cost-effective agricultural implements that would reduce drudgery attached with agriculture.

“We try to develop simple and low-cost technologies.

For example, we have developed processing equipment for cassava to remove drudgery right from the planting to the final stage of processing,” he said.

He said cassava planters, harvesters, and tractors had been developed by Nigerian engineers at NCAM.

The centre has also developed cassava peeling machines in different categories of sizes and capacities.

To a very large extent, he added, the locally made machines had been more effective because they were demand-based and low cost.

The problem, he said, is poor awareness of some farmers about new and cheaper technological devices.

The imported cassava planter and harvester, he added, could cost as high as N6 to N8 million, but the ones produced locally could be about 3 million or even lower.

NCAM, he said, had discovered that the locally fabricated tools work better than imported machines, saying, “This is because we have put into consideration the nature of soil texture, the topography and many other ecological factors that affect their use.”

The centre has developed complete processing machines for cassava, for rice, cashew, and for yam processing, and had made a machine that could make yam heaps.

“Nigeria happens to be the largest producer of yam in the world, and there is no machine in the world that can make yam heaps. But National Centre for Agricultural Mechanisation (NCAM) has just produced a yam heap molding implement,” he explained.

Technology incubation centres

OLAIFA said NCAM was supposed to mass-produce the machines it had developed, “but for now, we have not been encouraged to mass-produce them. What we do sometimes is that we organise training, and through the training, other local fabricators are trained to duplicate our prototypes.”

Mr Adeniji Lucas, founder of NIJI Farms Ltd, who is also a fabricator, said the government should look inward, discourage importation of basic agric machines that the country could produce, and encourage local fabricators by setting up several technology incubation centres.

He advocated provision of stable power supply, water, security and other tool-making infrastructure at the centres to revolutionise mass production of agric equipment.

Mr Anthony Egba, former Technical Adviser on Cassava Value Chain Development to Akinwumi Adesina, former Minister of Agriculture, said

local machine makers had the capacity, and the locally made ones are more rugged and adaptable to the ecology of Africa.

He pitched tents with others on functional and well equipped technology incubation centres across the country, adding that adequate financial facilities from the Bank of Agriculture and Bank of Industry would also boost their capability to produce more affordable and durable agro-industrial machinery.

Egba added that the government should ensure the local production of steel, for this constitutes the bulk of the materials used in producing agro-machinery.

“When our steel industry is functional, the materials used in fabrication could become cheaper and this affects the quantity we could produce and the price as well,” Egba said.

Mobilising AMEFAN for agric value chain development

MR Adeniyi said AMEFAN had been able to come together, but the government had not responded to moves to make them coherently relevant in the agricultural sector.

He suggested the association should be mobilised for agricultural equipment manufacturing, and that the government should discourage importation of substandard machines from China to protect home companies and jobs.

END

Be the first to comment